Project

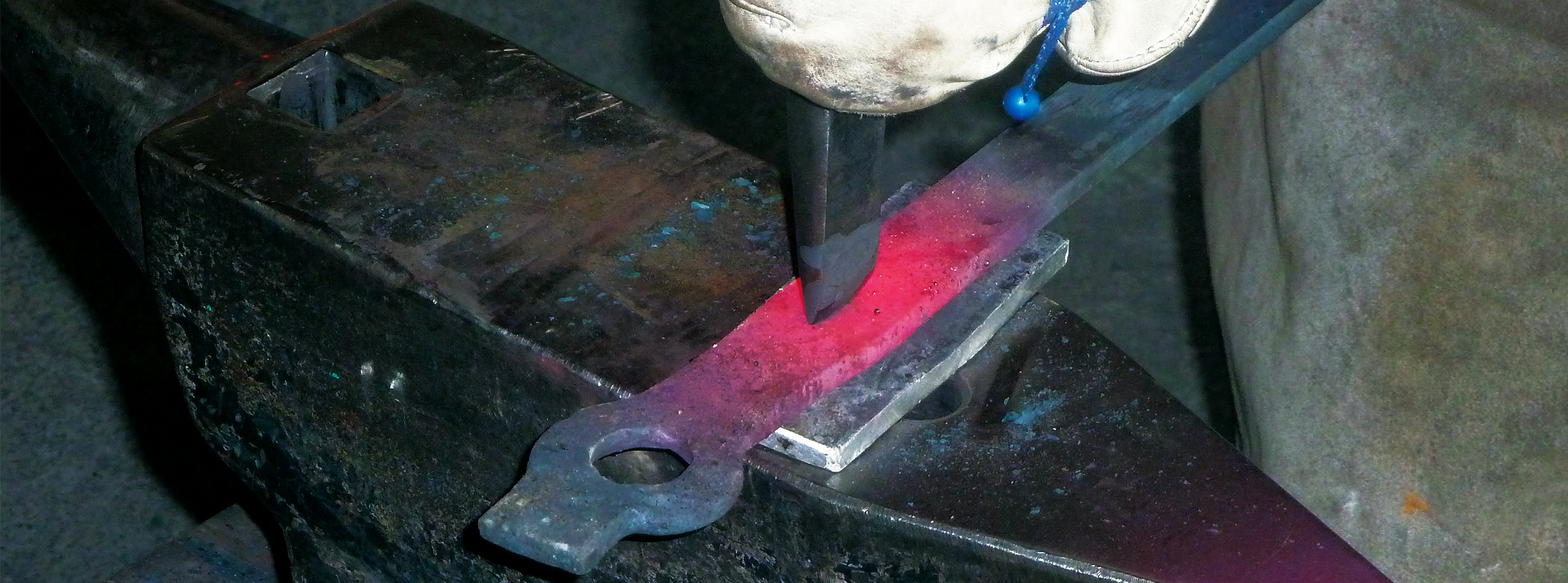

The cooling of forged parts. Forged parts have to be cooled from approx. 1,200 °C to below 600 °C. By calculating and with the help of a simulation program, the previous motor output could be reduced by 25 percent. This was accomplished by aligning the nozzles differently and thanks to optimised piping. At the same time, the volumetric flow was increased by 3,000 m³/h to 4,200 m³/h. The benefit for the customer is thereby the increased throughput together with an energy saving.

Elektror's Performance

- Design of the ventilation system

- Calculation and simulation of the cooling performance

- Construction of the cooling unit

- Assembly and delivery

Content of the cooling module

- Low pressure blower S-LP 225/92-50/5.5

- Piping incl. y-pieces/manifolds etc.

- Mounting base for wall assembly