The future starts now

Our service goes well beyond perfect process handling. With our own ventilation lab as well as a research and preliminary development department, we are able to simulate and investigate system components so as to provide customers with that crucial additional expertise. This is why our research is always geared closely towards applications so as to tackle practical issues.

We mainly focus on efficiency, acoustics and durability. In so doing we look at the correct design and flow optimisation, noise reduction, sound insulation, impeller stability and bearing durability. We have modern simulation tools available to us to tackle challenging projects, and we use these to make flow and strength calculations as the basis for ensuring that a ventilator meets our customers’ needs precisely.

Our services

Through our “Technological Development and Simulation” research and pre-development department set up in 2015 at the headquarters in Ostfildern we address the three crucial issues for our new and existing products - efficiency, acoustics and service life - and provide support for customer-specific applications and problems with designs, simulations and measurements.

We support you in the following areas:

- Flow simulation of fans and applications

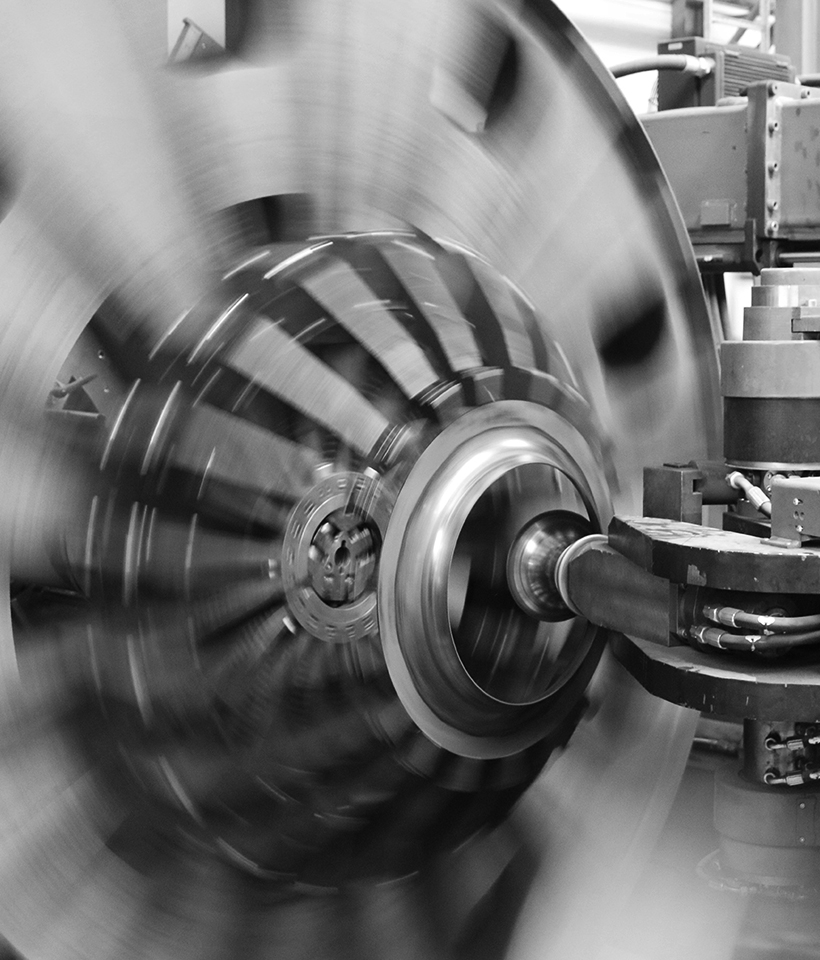

- Stress analysis and evaluation of the impeller strength

- Performance measurement of fans and electric motors

- Sound pressure level measurement with five microphones

- Vibration measurement and determination of natural frequencies

- Impeller cycle test for determining the fatigue strength

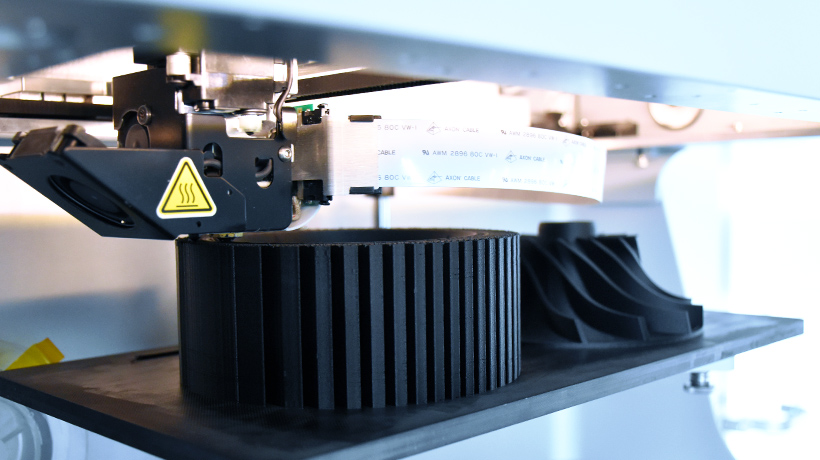

- Prototyping with carbon fibre reinforced 3D printing