Storing biogas

Electricity and heat from biomass made up a share of around 46 per cent of the renewable energy in Germany in 2018, according to the German Federal Environment Agency. The biogas is derived from biomass. Biomass consists of renewable raw materials, and also biowaste, manure and sludge.

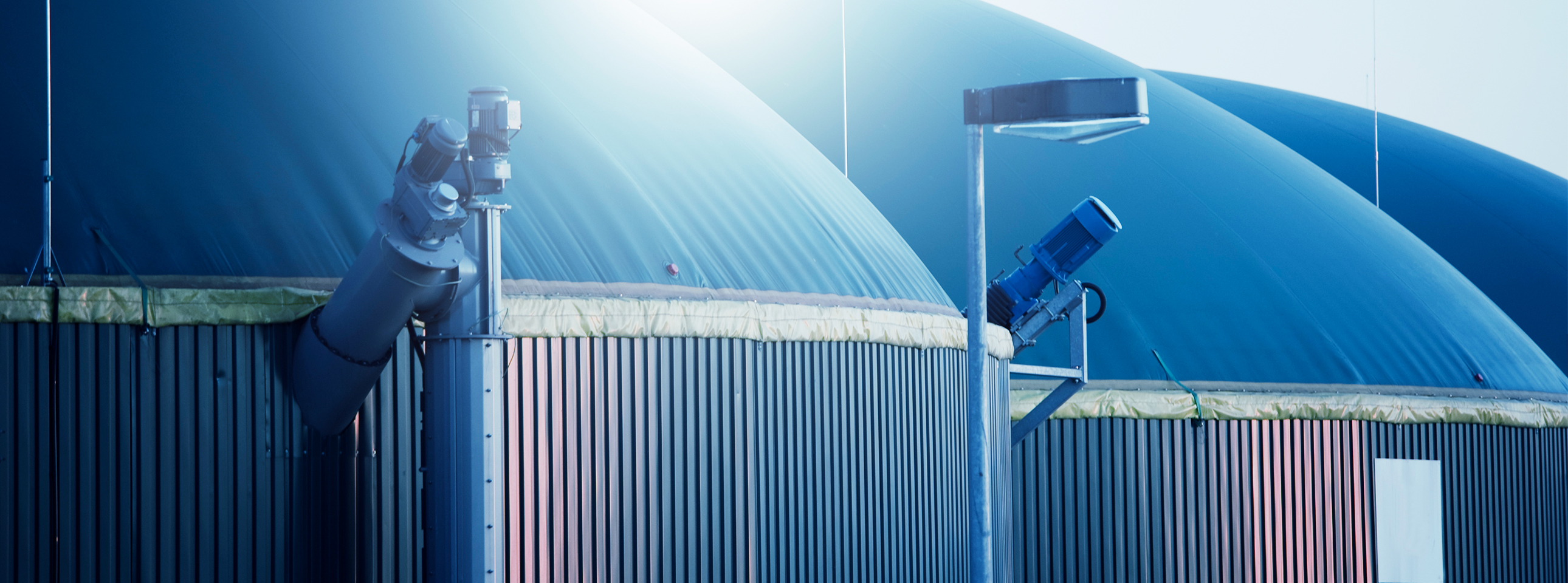

Its actual generation occurs through the fermentation of biomass. The product arising from this is combustible gas (methane). The energy can be derived from the combustion of methane in a co-generation plant. During the fermentation process in the biogas storage facility, the volume contained within it changes. For this reason, the storage facilities have been fitted with a flexible inflatable film cover and a double membrane. The inner membrane is installed to be gas-tight and can expand or retract during methane generation. Placed on top of this is an outer membrane, which protects against rain, wind and other weather conditions. The air cushion is kept constant between the two membranes by Elektror fans and the ATEX PCS. Methane can escape through leaks in the membrane and turn into an explosive methane–air mixture. This is why biogas plants need to be inspected for explosion and fire protection every three years.

ATEX Pressure Control System

The challenge for the Elektror experts was to develop a system which keeps the air pressure in the air cushions constant while simultaneously being suitable for an ATEX zone. Because of this requirement, the ATEX Pressure Control System (or ATEX PCS for short) was developed. The prevailing pressure is detected using a pressure sensor and passed on to the PCS. The PCS then regulates the ATEX support air blower, so that the predefined pressure can always be maintained.

The PCS is located outside the ATEX zone. The pressure sensor and fan are installed directly at the biogas storage facility. All components in the ATEX zone are ATEX-certified in line with EX II 2G c T3. The entire system can be supplied both with and without stainless steel suction filters. Depending on the blowers, the maximum pressures can be set between 50 to 2,500 Pa. The maximum air output of the blower is 600 to 2,700 m³/h.